Stage Floor Box

Stage floor boxes play a crucial role in any performance venue or event space. These boxes provide panels with various connectors and connection ports, allowing for the effective management and connection of a variety of electrical and audio equipment on the stage.

Improperly installed floor boxes can lead to various issues such as unstable connections, electrical hazards, and aesthetic problems. It's essential to ensure that floor boxes are installed correctly to prevent these issues and maintain the safety and functionality of the performance space.

Issues Caused by Improperly Installed Floor Boxes

Improperly installed floor boxes can cause various problems in performance or event venues. These issues typically arise from not performing accurate shop-drawings and installation. The main causes include cable exposure and unstable fixing.

Challenges with Equipment Installation in Floor Box Undersides

When installing equipment such as video converters or direct boxes underneath floor boxes, problems can arise due to complex cables and unfixed equipment.

Importance of Stability and Design in Floor Box Interiors

The interior of a floor box is designed to accommodate multiple connectors and should be securely fixed as connections and disconnections occur frequently. Additionally, the internal panels should be sufficiently robust.

Load-Bearing Capacity of Stage Floor Boxes

Stage floor boxes in performance venues should be able to withstand approximately 200kg of load.

Well-Installed Floor Boxes

Direct Connection of Floor Box Wiring and Secure Attachment of Each Conduit Pipe

Floor boxes must be securely fixed in the designated positions in coordination with other processes. A separate pull box should be used for securing connectors for wire management underneath the floor box, providing ample space for convenient maintenance.

Additionally, floor boxes must be grounded.

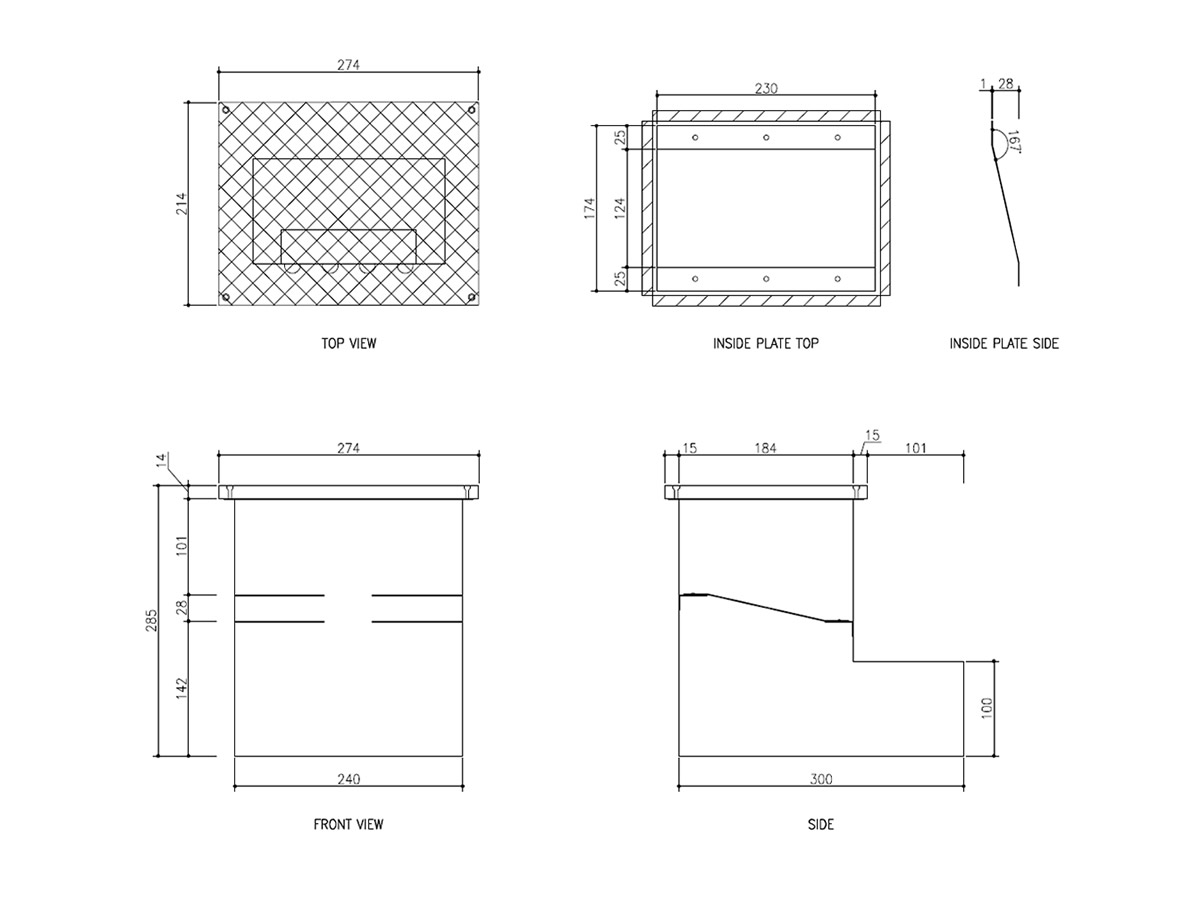

Floor Box Diagram

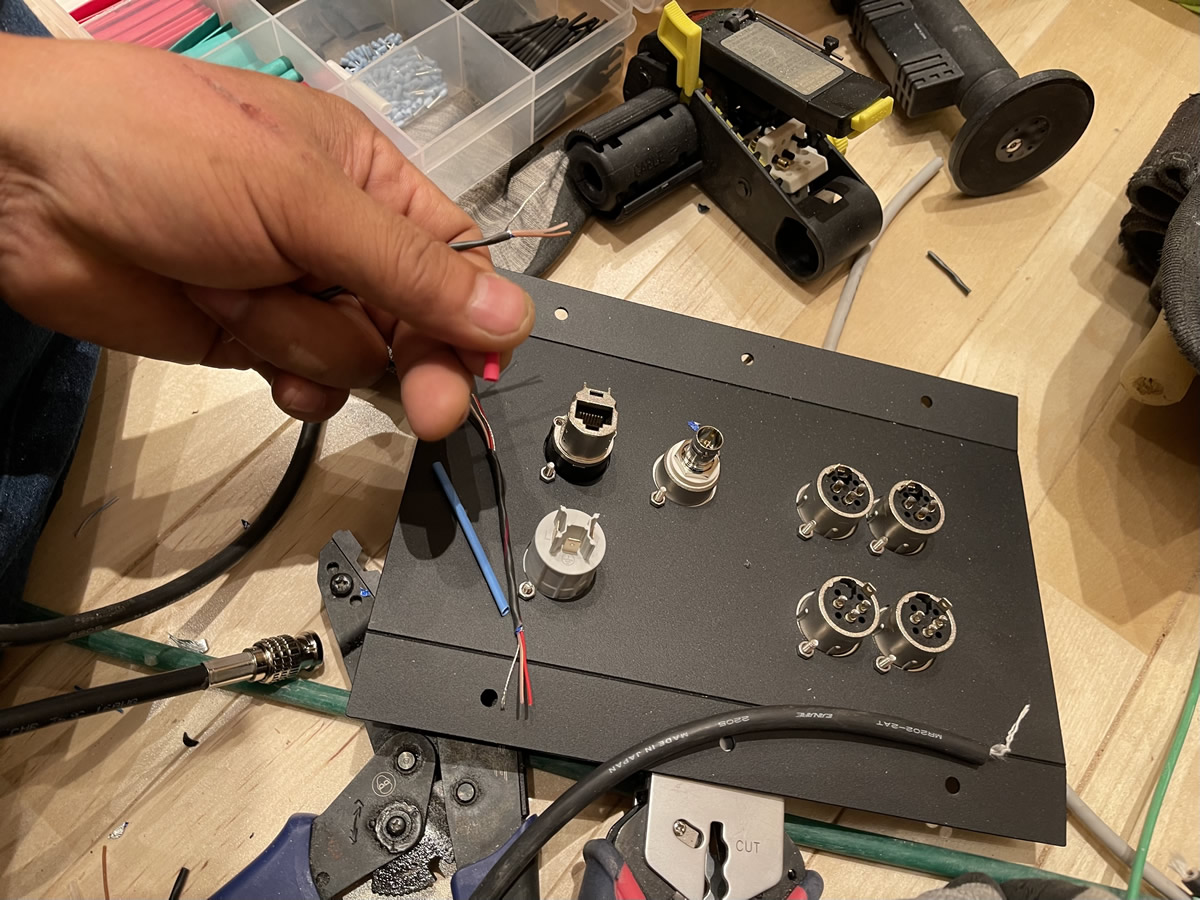

Internal Panel Inside the Floor Box

Stage Floor Box Panel - Front View

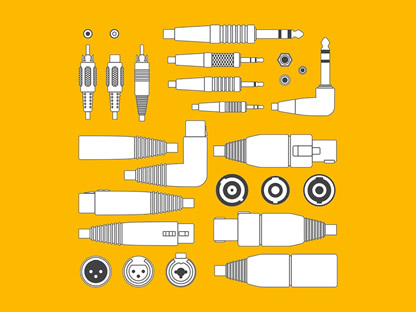

Floor boxes should be designed with user convenience and safety in mind. For this purpose, the panel inside the floor box should clearly display the name of the floor box and connector types. This allows users to quickly identify the necessary connections, improving operational efficiency. Additionally, cables should be thoroughly labeled to clearly indicate which cable is connected where, reducing the risk of malfunction or connection errors.

Furthermore, it's advisable to use dust caps for less frequently used connectors to protect them from dust and foreign particles. This helps prevent damage to connectors that are not in use for extended periods.

When designing floor boxes, these factors should be taken into consideration to provide users with a safe and efficient operating environment.

Stage floor box panel - Rear